Factory Sales High Strength/Heavy Duty/Black Painting/Galvanized/Carburized Lifting Link Welded Alloy Steel Traction Chains with CE/ISO for Mining Use/Hoisting

Package Size 40.00cm * 15.00cm * 10.00cm Package Gross Weight 6.000kg Product introduction 1. Size 6mm to 22mm, alloy st

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | FST-G80 |

| Feature | Heat Resistant |

| Chain Size | 10mm-48mm |

| Structure | Welded Chain |

| Color | Self Color |

| Manufacturer | Yes |

| Lead Time | Within 25 Works Days After Receive Deposit |

| Payment | T/T |

| Trade Term | Fob, CFR, CIF |

| Safety Factor | 4:1/6:1 |

| OEM/ODM | Yes |

| Packaging | Packed in Wooden Case/Iron Drum, Then in Pallets |

| Place of Origin | China |

| Size | 10mm-48mm |

| Brand | Fst |

| HS | 73158200 |

| Specificate | 10*40-48*152 |

| Process | Welded+Heat Treatment+Surface Treatment |

| Certificate | ISO9001 |

| Product Name | Mine Chain/Lifting Chain |

| Transport Package | Packed in Wooden Case/Iron Drum, Then in Pallets |

| Specification | 10*40-48*152 |

| Trademark | First Rigging |

| Origin | Shandong, China |

| HS Code | 73158200 |

| Production Capacity | 150ton/Month |

Packaging & Delivery

Package Size 40.00cm * 15.00cm * 10.00cm Package Gross Weight 6.000kgProduct Description

Product introduction

1. Size 6mm to 22mm, alloy steel 25MnV or 20MN2, 24mm to 42mm using imported German 23MnNiMoCr54 alloy steel 2. Surface: self-coloring, painted black; Plastic coated galvanized 3. Safety factor :4:1 4. Comply with EN818-2 standard 5. Standard G80 or customer requirements, at least one meter apart 6. Serial number printed on high power round steel chain; All production and certification dates are also recorded. Mark once per Meter run.Lifting and rigging chain has been one of the most popular rigging products on the market for many years, mainly due to its strength, durability, and ease of use. All our alloy steel rigging and lifting chain is heat treated to offer industry leading load capacity and durability. Some steel rigging chains are approved for overhead lifting, while others are not, so it is important to always know what type of lifting chain your specific rigging application requires

Product specification

| Product name | 10mm Grade 80 Chain Lift Anchor Transport Welded Alloy Carbon Stainless Steel Heavy Duty Lifting Chain with Hook |

| Grade | Grade 80 Grade 100 or as your request |

| Size | 4/5/6/7/8/10/11/12/13/16/19/20/22/28/32mm or as your request |

| Color | Black , Self color ,Yellow , Red or As your request |

| Length | Custom |

| Material | Alloy steel, 20Mn2A, Stainless steel , high carbon steel . |

| Surface treatment | Blacken finished ,Hot dip galvanized , electroplating , powder coating ,black painted . |

| Structure | Welded chain |

| Process | Fully automatic deburring |

| Sample | Support |

| OEM&ODM | Support |

| MOQ | 2T |

| Standards | G30 G43 G70 G80 chains NACM/SATM chains |

| Certificate | ISO9001 & CE |

| Method of payment | T/T ,Western Union. |

| Key words | 10mm Grade80 Chain Lift Anchor Transport Welded Alloy Carbon Stainless Steel Heavy Duty lifting chain ;Single Leg G80 G100 EN818 polished Electric hot dip galvanized black finished painted lifting chain;Us standard black self color plated zinc strong chromate coating 1leg 2legs 3legs 4legs lifting chain |

3. Finishing is not only smooth surface, but also improve its wear resistance, corrosion resistance, rust resistance to obtain high hardness. 4. All kinds of hooks, rings, widely used in vehicles and boats, machinery, mines, ports and other lifting places. Purpose of use High strength chain for carrying heavy loads Used for heavy lifting in mines and construction sitesGrade G80 lifting chain is an indispensable lifting device when lifting heavy objects. It is made of high-quality alloy steel(manganese steel,etc.),and the quality is strictly controlled throughout the whole process. Only in this way can the lifting chain reach Grade 80 international standard.

Company Profile

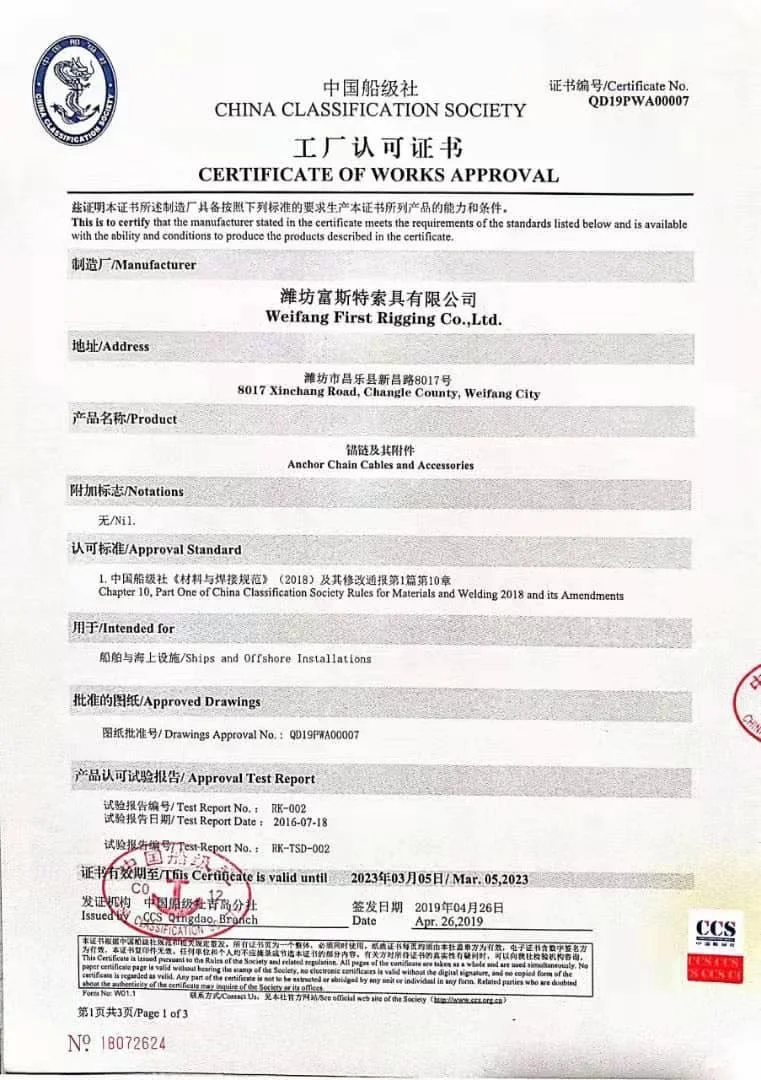

Founded in 1998, Weifang Fuster Rigging Co., Ltd., formerly known as Changle Chain Factory, is located in Changle County of Shandong Province known as "The Gem City of China", and specializes in producing and marketing chain and rigging related products at home and abroad.Our company has independent import and export operating rights, and can handle the certifications of CCS, LR, DNV and other famous classification societies for products. Our products are sold to dozens of countries such as Europe, America and Middle East as well as more than ten provincial and municipal regions in China, and are widely applied to the fields of ships, steel, petrochemical industry, coal mine, etc.In the principle of "Quality-honoring & Promise-keeping", our company meets the requirements of all the customers through service innovation, changes the original production state through technical innovation, improves the product quality through process innovation, and continuously goes to standardization, elaboration, process and scientification through the business thought of constant innovation.Absolute sincerity will move a heart of stone. Our company is willing to cooperate with domestic and foreign new/old customers in utmost sincerity, to create a common future!

The production process

How do we control quality:

a) Pay attention to adaptation for manufacture process

b) Approval report for shipment

c) Third party inspection is accepted

d) Keeping quality guarantee for a long period

e) Guaranteeing quality inspection of each product before assembly and packing.

f) Comply with ISO 9001

Packing and transportationWhy choose us?

1.Stable Brand Cooperation2.High Quality Production3.Excellent Service4.High Quality Product

FAQ

1.How long is your delivery time?

A: Generally it is 5-10 work days if the goods are in stock. or it is 15-20 work days if the goods are not in stock, it is according to quantity.2.What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.3.What products do you supply?As mentioned above, Weifang First Rigging Factory is capable of supplying:√All kinds of marine supplies√Chains√Rigging hardwares√Fasteners√related hardwares

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.6.Where are you? Can I visit you?

A: Sure,welcome to you visit our factory at any time.

Certificate

Our foreign trade staff are all senior staff with more than 10 years of experience, and our foreign trade manager has more than 20 years of experience in foreign trade. In addition to providing you with the best products, we can also provide you with the best service